The Tonearm

The arm needs to be strong and rigid allowing it balance a relatively light weight cartridge at one end and a heavy counterweight at the other.

Although strength and rigidity are a requirement so is a low level of resonance and the ability to dampen vibrations emanating from the cartridge body into the arm and reduce their return path back into the cartridge, which negatively effects the stylus / cantilever assembly.

The arm is also a tube which carries internally the fine wiring from the cartridge body to a 5 pin tonearm connection socket mounted within the base of the tonearm, or alternatively to a pair of female RCA Phono sockets.

The internal wiring used should be flexible and not impede the motion of the arm, some manufactures incorporate the wiring into the anti-skating adjustment of the arm.

Some arm designs incorporate an inner and outer tube, designed and manufactured as a composite of materials such as wood, stainless steel, aluminium and carbon fiber all of which can aid in the reduction of vibrations along the arm length.

Tonearm Sections

- The cartridge mounting point or head shell position.

- The arm or wand.

- Tonearm Bearing or Unipivot point.

- Counter weight.

Tonearm Designs:

(i) or Straight Type

The “i” or Straight type tonearm is available in 9”, 10” and 12” lengths.

The 9” tonearm offers slightly more stability due to its shorter arm or tube length and is slightly less prone to internal, structural and airborne vibrations, also it can be fitted to a wider range of smaller or larger turntable plinths.

10’’ and 12’’ tonearms help reduce the offset error at the inner and outer null points which results in less tracking distortion and a slightly more musical and natural sounding performance.

The negative side is that they are heavier, less stable and are more prone to internal, structural and airborne vibrations requiring the use of lower-compliance cartridges plus a far more precise setup procedure.

They also require a larger turntable plinth to accommodate them.

(J) & (S) Type

The characteristic “J” shape of this tonearm design is due to the angled headshell section at the end of the tonearm.

The J and S characteristic designs allow the design engineers to accommodate the overall length of the arm in a reduced area. It also allows for a longer pivot point distance and increased weight compared to a straight arm, helping reduce lateral and vertical tracking distortion plus allow the use of a detachable headshell as the cartridge offset angle has been designed into the shape of the tonearm.

Tonearm Bearing Designs

Parallel

Gimbal (Most common)

UniPivot

Magnetic

For the purposes of this blog we shall concentrate on the most popular of designs, Gimbal & UniPivot

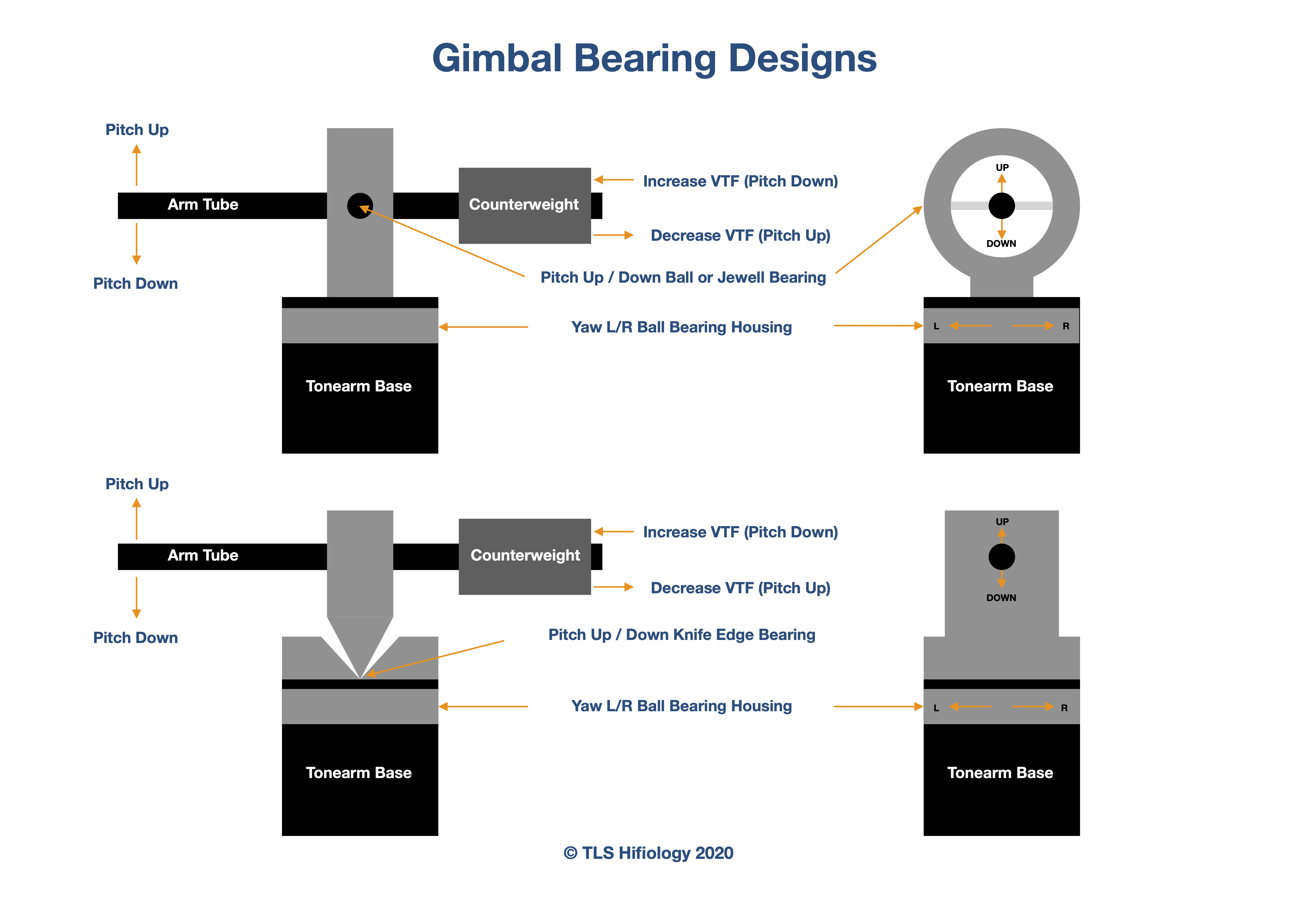

The Gimbal Design incorporates two bearing assemblies positioned at 90° to each other.

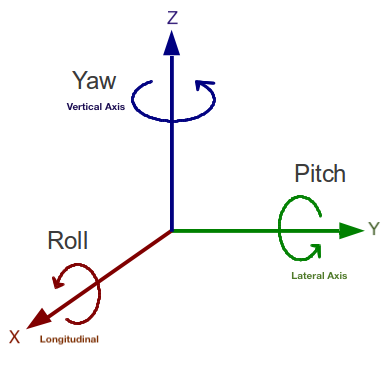

The 1st or top bearing allows Up and Down movement or Pitch of the tonearm in the Lateral or Y axis & the 2nd or base bearing allows the Left to Right or Yaw movement of the tonearm in the Vertical or Z axis.

Pitch - Up & Down (Lateral- Horizontal - Y Axis)

Yaw - Left to Right (Vertical - Z Axis)

Gimbal Bearing Design (Bearing Types)

1.Ball Bearing (Stainless Steel, Ceramic)

2.Knife Edge Bearing

3.Jewelled Bearing (Sapphire, Ruby)

Ball Bearing (Stainless Steel, Ceramic)

Gimbal Ball bearing designs are by far the easiest to set up and align.

At the tonearms pivot point are two sets of bearings at 90 degrees to each other. 1st set of bearings allows movement in the Vertical axis and the 2nd set of bearings allows movement in the Horizontal or Lateral axis.

Stainless steel bearings as well as smoother ceramic bearings are used to obtain frictionless movement within the bearing housing.

With any bearing assembly there will always be movement caused by Internal and external vibrations.

A well designed bearing housing will aim to minimise the effects of these vibrations, which can cause what is known as ‘bearing chatter'. This is when the bearings move against each other in different directions within their housing. The movement is caused internally by the recorded vibrations within the groove of the record being transferred from the stylus assembly to the arm via the cartridge and externally by structural and airborne vibrations.

Knife Edge Bearing + Ball Bearing (Stainless Steel, Ceramic)

At the tonearms pivot point the arm rests upon an inverted triangular bracing section that is at 90° to the arm, and is part of the top section of the tonearm pivot assembly which allows the arm to freely move in the vertical plain.

The apex of the inverted triangular bracing section rests as if on the sharpened edge of a knife within a V shaped section which is the base part of tonearm pivot assembly which allows the arm to freely move in the lateral or Horizontal plain.

Jewelled Bearing (Sapphire, Ruby)

Some manufacturers use Sapphires or Rubys positioned at the tonearms bearing points, because of their durability, smoothness and frictionless properties to further enhance the tonearms performance.

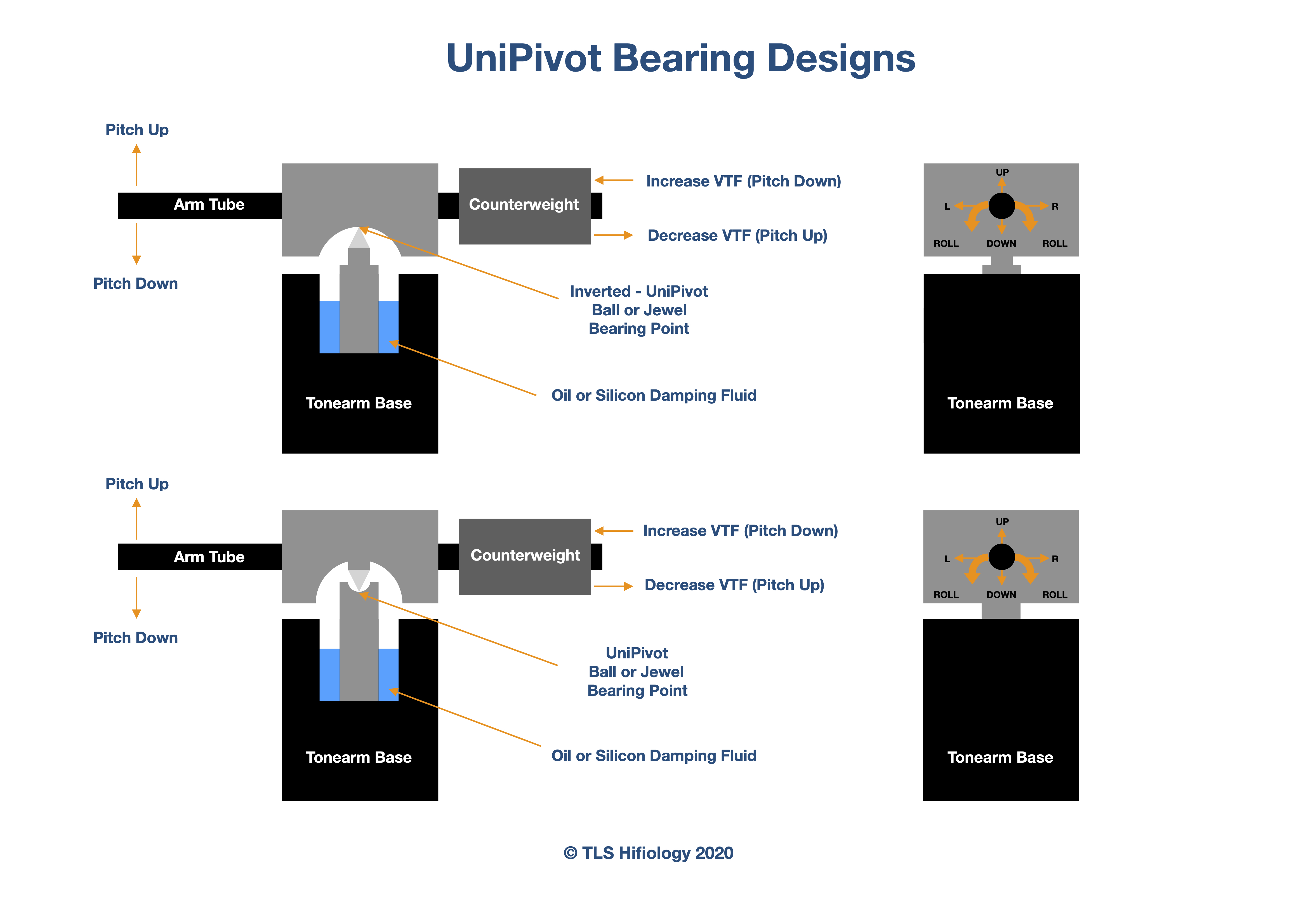

The UniPivot Design rests the tonearms bearing onto the point of a needle.

This design allows the tonearm to move freely in the X,Y and Z axis.

Roll - Side to Side (Longitudinal - X Axis)

Pitch - Up & Down (Lateral- Horizontal - Y Axis)

Yaw - Left to Right (Vertical - Z Axis)

Unipivot Bearing Design

The Unipivot design although allowing additional freedom of movement does require far more setup time.

It needs to be precisely balanced with regard to Azimuth and Vertical Tracking Force. This process takes time and patience due the tonearms total freedom of movement in the X,Y and Z axis, as it pivots on its hardened steel pin point.

The stability and balance of the tonearm can further be enhanced by lowering or hiring the tonearms centre of gravity above or below its pivot point.

Unipivot designs can also be described as Low or High centre of gravity arms.

Some designs incorporate very low friction miniature steel or ceramic ball bearing housings at the point where they rest upon the hardened steel pin, or pivot point.

Tonearm Fluid Damping

Both Gimbal and UniPivot tonearm designs utilise oil or silicon fluid within their assembly to dampen and absorb vibrations and resonance within the tone arm and the supporting base.

Hifiology - Quicklinks

Record Player, Record Deck, Turntable

https://www.thelisteningsuite.ie/record-player-record-deck-turntable/

The Stylus - Shapes, Types

https://www.thelisteningsuite.ie/the-stylus-shapes-types/

The Stylus - Needle in the Groove

https://www.thelisteningsuite.ie/the-stylus-needle-in-the-groove/

The Cartridge - Moving Magnet or Coil

https://www.thelisteningsuite.ie/the-cartridge-moving-magnet-or-coil/

The Cartridge - The Assembly

https://www.thelisteningsuite.ie/the-cartridge-the-assembly/

The Tonearm - Shapes & Sizes

https://www.thelisteningsuite.ie/the-tonearm-shapes-sizes/

The Tonearm - Geometry & terms

https://www.thelisteningsuite.ie/the-tonearm-geometry-terms/

The Phonostage

https://www.thelisteningsuite.ie/the-phono-stage/